| CAS NO. | 136-53-8 | ||||||||||||||||

| Molecular formula | C6H9NO2 | ||||||||||||||||

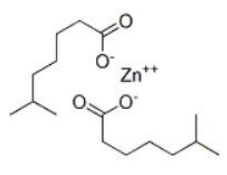

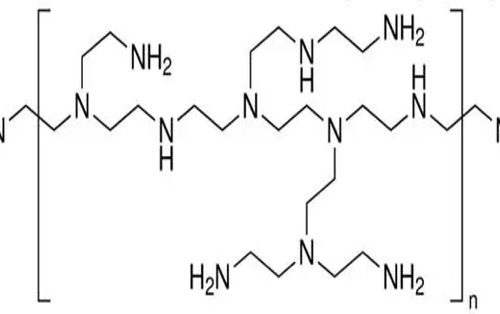

| Structural formula | |||||||||||||||||

| Properties |

|

||||||||||||||||

| Storage | The packing specification is 25kg plastic drum, 200Kg plastic drum, or user-specified packaging. This product should be stored in dry, cool, avoid light and high temperature closed conditions, be sure to avoid contact with acids and oxidants. From the date of production, the storage period of the product under the original packaging conditions is 12 months; Non-flammable and explosive products, but there is a certain corrosiveness, belonging to the general danger. | ||||||||||||||||

| Application | 1. Common in all kinds of air-dry paint; Suitable for white or light paint; 2. Curing accelerator and curing catalyst of unsaturated polyester resin adhesive can promote aliphatic isocyanate crosslinking and shorten curing time; 3. Used with calcium isocrylate as a heat stabilizer for synthetic resins. |

||||||||||||||||

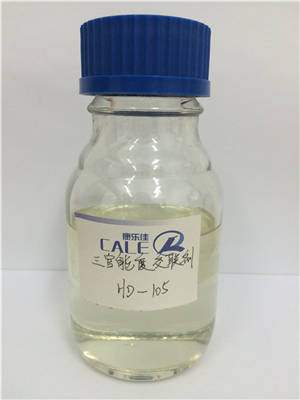

| Product Presentation

This product has a stable acid value and molecular weight, excellent storage stability, compared with traditional zinc naphthenate, has the following advantages: 1. Light color, small smell, high content. 2. The use of light paint has better characteristics, can reduce the color of the paint film, improve the luster; 3. It can also be used as a catalyst for polyurethane coatings and elastomers, which can promote aliphatic isocyanate crosslinking and shorten the curing time; It can also be used in the production of synthetic resin liquid heat stabilizer. Method of Application This product is irritating and corrosive to the skin and mucous membranes, should be handled carefully and avoid direct contact with the skin and eyes, as far as possible in a ventilated environment. Pay special attention to oral and nasal inhalation, and wear special masks, gloves, and protective clothing. Friendly Reminder This information is true and accurate based on our knowledge, however, we do not accept responsibility for any recommendations or statements made, as the conditions and methods used are beyond our control, and the user is solely responsible for evaluating the usefulness of the product in terms of application and performance as required |

|||||||||||||||||

Product Categories

About Us

Ningxia JOIE Material Co., LTD.,established in May 2018, is situated in the Ningdong Energy and Chemical Industry Base in Ningxia. The company owns registered trademarks and holds multiple authorized patents. Its primary business involves the research, development, and production of aziridine and imidazole series products, which find extensive applications across various fields. Having passed multiple management system certifications, the company is committed to becoming a leading global provider of specialty chemicals.

Zinc Isoocatanoate

| Appearance | Light yellow to colorless transparent liquid |

| Metal Content | 12% |

| Melting Point | 78-81℃(Press:1.3Torr |

| Water Content | ≤0.5% |

| Solubility | Soluble in water, alcohol, etc., no precipitation |

Related products

Site Map

Contact Us

Phone: 400-011-7633

E-mail: sales@holdenchem.com

- Business hours:Monday to Friday, 8:30 AM – 6:00 PM

- Address:East side of Hongyan Road, Yuanyang Lake New Material Industrial Park, Ningdong Town, Lingwu City, Yinchuan, Ningxia

浩登材料 | 康乐佳材料

Ningxia Zhuoyu New Material Technology Co., Ltd. All rights reserved © 2022

Site Map

Ningxia Zhuoyu New Material Technology Co., Ltd. All rights reserved © 2022